A Vertically IntegratedSeed Production Facility

From start to finish, we provide complete brand solutions.

Who We Are

We Are Custom

Our Production Acres and Facility are designed by us to bring flexibility to all our customers. We have developed innovative processes and systems to provide solutions for any needs. Whether you are looking for acres for experimental hybrids or the production know-how to apply specific treatment, our seed professionals have the knowledge, skill, and resources to turn your goals into results. We do not provide one-size-fits-all solutions; our team listens to your needs and tailors our services to meet your brand’s goals.

About us

Total Seed Production is the result of over 89 years of commitment to constant improvement, hard work, and a longing for growth.

We are a first-class innovative seed producer. Our drive and commitment are to create superior quality seed and deliver tailored services to meet our customer’s specific needs.

- DEDICATION

- SEEDSMANSHIP

- SERVICE

- GROWTH

Yesterday to Today

Expansion and Customer Success

Since the seed of our future was first planted in 1936, we, and the generations before us, have strived to bring our customers the best seeds and service in the industry. Now, we have grown, learned, and continue to strive for improvement for our team, our customers, and the future of TSP.

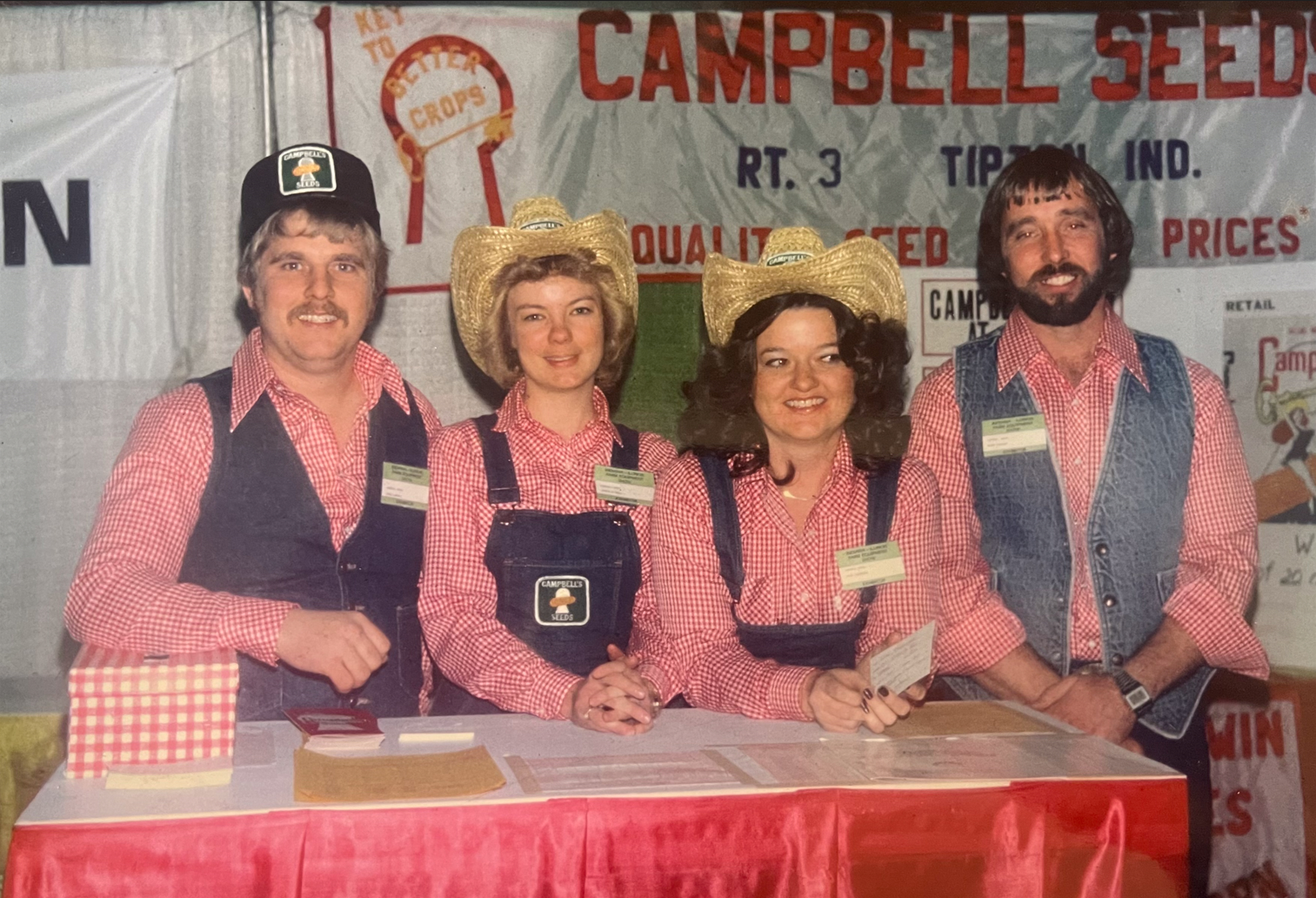

Campbell's Legacy

Elevating Seed Innovation

Unprecedented Bagging

Soybean Expansion Triumph

Wholesale Revolution Ignites

Continuing Family Legacy

Storage Expansion

New Family Alliance

Enhanced Processing Infrastructure

Office Transformation Journey

Dryer Capacity Boost

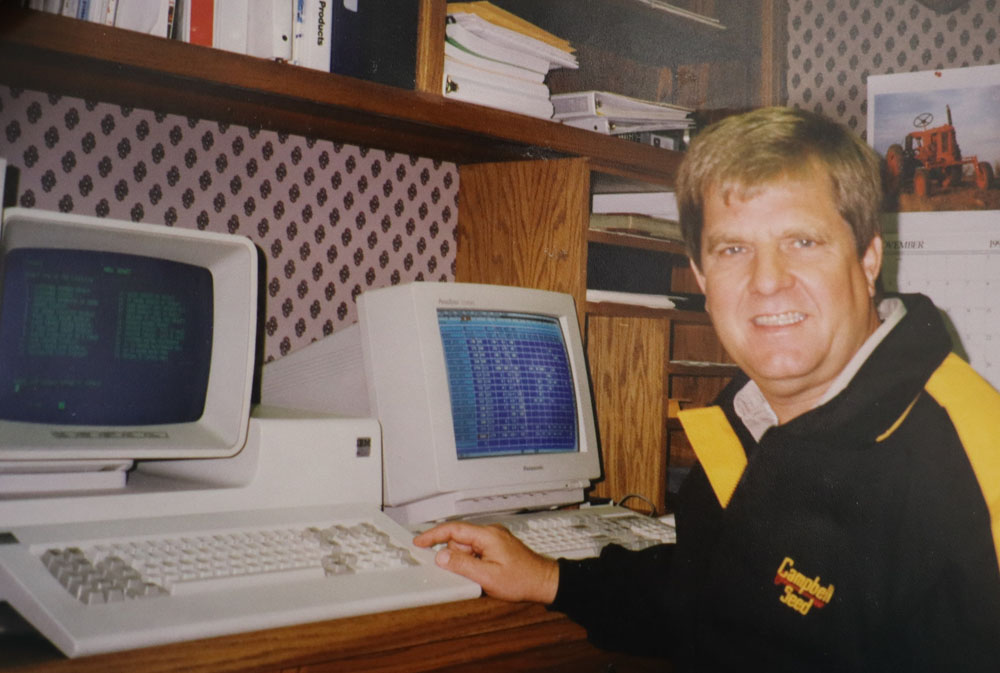

Tech Upgrade Success

Office Revamp

Generations Expand Further

Streamlined Processing Advancements

Expanded Warehousing Capacity

Brand Transition: New Horizons

New Generation Unites

Irrigation Innovation

Quality Assurance Achievement

In-House Chemical Advancements

Sustainable Solar Power

Expanded Facilities Investment